Introduction

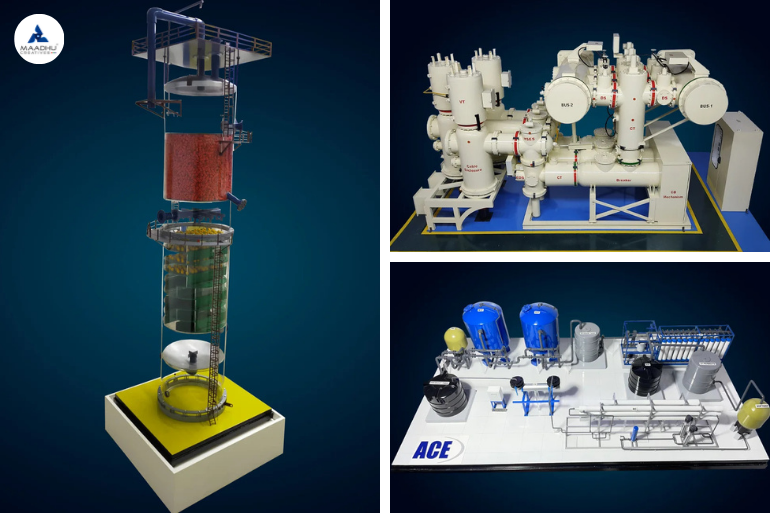

Piping model making is a critical aspect of engineering design that enables the creation of detailed visual representations of piping systems. These systems are integral in various industries, including oil and gas, chemical processing, and water treatment. By developing precise models, engineers can effectively predict how a piping system will operate before actual construction begins. This practice not only saves time and resources but also enhances safety and efficiency in the design process.

Why Piping Model Making is Important

Understanding the significance of piping model making can greatly influence project outcomes. Here are some key uses:

Enhanced Communication

One of the primary benefits of piping models is their ability to facilitate clear communication among all project participants. When everyone can visualize the same design, misunderstandings are minimized. This clarity is especially crucial in large teams where multiple stakeholders, including engineers, clients, and contractors, are involved. Effective communication ensures that everyone is aligned with the project goals and specifications, leading to a smoother workflow.

Early Problem Detection

A model creates allows engineers to spot problems early when the design is still done. A case on point would be a pipe installation being done wrongly that will cause some sort of conflict with some other equipment or systems. Early on, resolutions of this kind of conflict will help avoid change and delays in the construction process, or rather during the building process. It thus saves much time and further improves the general quality of the final product produced.

Regulatory Compliance

Many industries face strict regulations governing their piping systems. Piping model making helps ensure that designs comply with these regulations, which reduces the risk of fines and enhances safety. Regulatory compliance is not just a legal obligation; it is also crucial for maintaining the integrity of the systems and protecting public health. By adhering to industry standards through effective modeling, organizations can avoid potential legal issues and ensure the safety of their operations.

Streamlined Design Process

A well-constructed model simplifies the design process. It allows engineers to make adjustments and optimize layouts before any physical work begins. This streamlined process means that teams can work more efficiently, as they can visualize the end result and make necessary changes in a digital environment. By using models, engineers can also explore different design scenarios, leading to more innovative solutions.

Usage of Piping Model Making

Piping model making is utilized across various industries for different applications. Here are some key uses:

Oil and Gas

In the oil and gas sector, piping models are essential for visualizing complex systems that transport oil and gas. These models play a crucial role in planning pipelines that minimize environmental impact and ensure efficient flow. Engineers can assess factors such as pressure, temperature, and material compatibility, leading to safer and more efficient designs. Moreover, models assist in evaluating the impact of pipeline placement on the surrounding environment, which is vital for regulatory compliance.

Chemical Processing

Chemical plants rely on intricate piping systems to transport various chemicals safely. Piping model making allows engineers to design systems that not only prevent leaks but also optimize the flow of materials. By simulating different scenarios, engineers can identify potential hazards and implement safety measures in the design phase. This foresight is invaluable in protecting both workers and the environment from chemical spills or leaks.

Water Treatment

In water treatment facilities, piping models are crucial for designing systems that effectively treat and distribute water. These models ensure that all components work together seamlessly, adhering to health and safety standards. By visualizing the entire system, engineers can identify bottlenecks or inefficiencies in the treatment process, leading to improvements in water quality and distribution.

Construction Projects

In construction, piping models are used to plan plumbing, heating, and cooling systems. Accurate models ensure that all components fit together perfectly, reducing the risk of errors during installation. Additionally, these models can be used to coordinate with other trades, such as electrical and structural engineering, leading to more integrated and efficient construction practices.

Training and Education

Piping models also serve as valuable training tools for new employees. They provide hands-on learning experiences about how piping systems function and are crucial for skill development in the industry. By using models, trainees can better understand the complexities of piping systems and learn how to troubleshoot issues before they arise in real-world applications.

Piping Model Making Helpful in Projects

The benefits of piping model making extend beyond initial design. Here are several ways in which it enhances project outcomes:

Improved Visualization

Models provide a tangible representation of the design, making it easier for stakeholders to understand and contribute feedback. This visual clarity can help in gaining approvals from clients and regulatory bodies, as they can see exactly what the project will entail. Improved visualization also aids in marketing efforts, allowing teams to showcase their work effectively.

Better Collaboration

When everyone can see the same model, team members can collaborate more effectively. This collaboration leads to improved decision-making and reduces the likelihood of errors. A shared visual reference helps align the team’s focus and encourages open discussions about the design, fostering a more collaborative environment.

Cost Efficiency

By identifying design flaws early, projects can avoid expensive rework and delays. This proactive strategy reduces both time and costs over the long term. Moreover, the ability to visualize the entire system allows for better resource allocation and budgeting, ensuring that projects stay on track financially.

Time Savings

The clarity provided by models can expedite the design approval process. With a clear visual, teams can move through stages more quickly, leading to faster project completion. Time savings in the design phase translate to quicker project delivery, which is especially critical in competitive industries.

Documentation

Piping models form a record of the process for designing. It can be pointed to in the future when there is any kind of maintenance or upgrade to make sure that the system continues to function more efficiently. Furthermore, this documentation is useful in training and in retaining conformity with industry regulations.

Conclusion

In summary, piping model making is an essential practice in engineering and design. It enhances communication, detects problems early, and ensures compliance with safety regulations. By investing time and resources into creating accurate piping models, teams can improve collaboration, save money, and design more efficient systems. Whether in the oil and gas sector, chemical processing, or water treatment, the benefits of piping model making are clear and impactful.

FAQs

- What is piping model making? Piping model making is the process of creating visual representations of piping systems to aid in design and engineering.

- Why is it important? It improves communication, identifies potential design flaws early, and ensures compliance with safety regulations.

- In which industries is it used? Piping model making is commonly used in oil and gas, chemical processing, water treatment, construction, and training.

- How does it save costs? By identifying issues before construction begins, it prevents costly rework and project delays.

- Can piping models be used for training? Yes, piping models are effective tools for training new employees about piping systems and their operations.