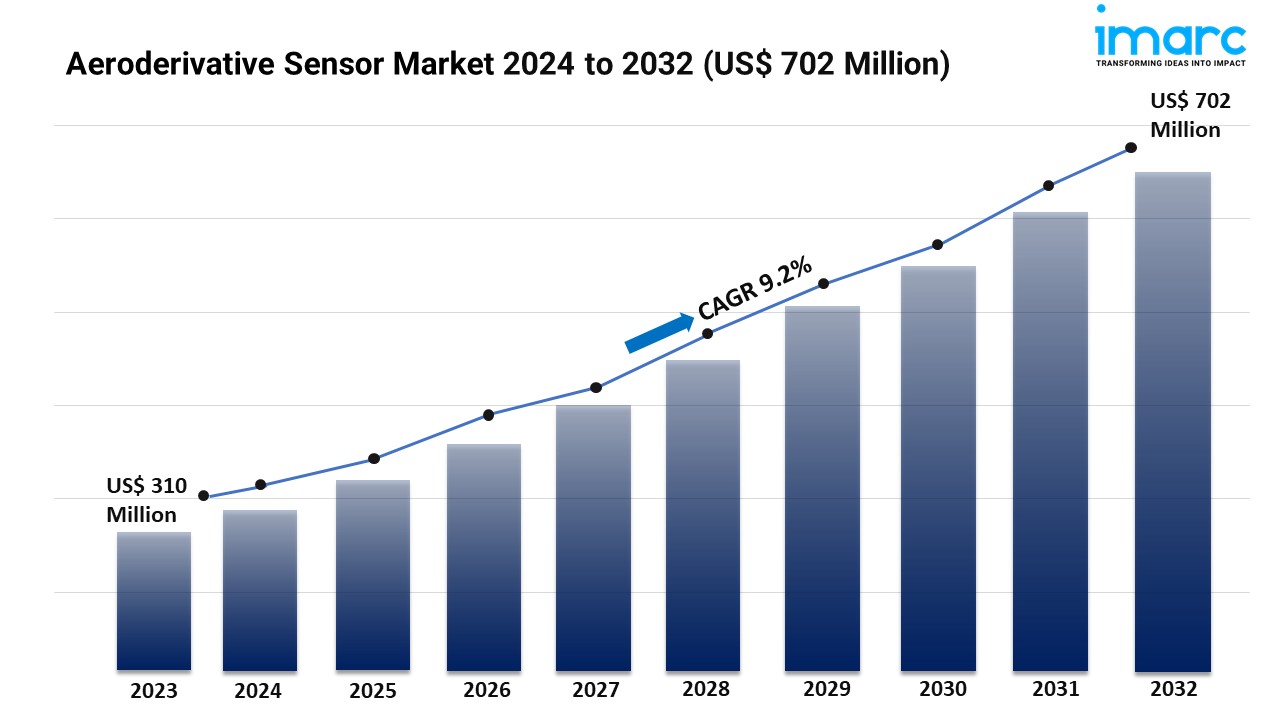

Global Aeroderivative Sensor Market Statistics: USD 702 Million Value by 2032

Summary:

- The global aeroderivative sensor market size reached USD 310 Million in 2023.

- The market is expected to reach USD 702 Million by 2032, exhibiting a growth rate (CAGR) of 9.2% during 2024-2032.

- North America leads the market, accounting for the largest aeroderivative sensor market share.

- Flame sensor dominates the sensor type segment, as they provide real-time feedback on flame stability.

- OEM holds the largest share in the aeroderivative sensor industry.

- Industrial remains a dominant segment in the market, as they require advanced sensor systems to monitor turbine performance, optimize fuel efficiency, and ensure operational safety.

- The rising demand for fuel efficiency is a primary driver of the aeroderivative sensor market.

- The growing utilization of aeroderivative gas turbines is reshaping the aeroderivative sensor market.

Industry Trends and Drivers:

- Growing use of aeroderivative gas turbines:

Aeroderivative gas turbines are increasingly being used in various industries beyond aviation, such as power generation, marine propulsion, oil & gas, and industrial sectors. These turbines offer the advantages of being lightweight, efficient, and capable of quick ramp-up times, making them ideal for flexible power generation. As their usage expands across these sectors, the demand for sensors that monitor and optimize turbine performance grows proportionally. Aeroderivative turbines require precise monitoring of key operational parameters such as temperature, pressure, and rotational speed to ensure efficient performance. Sensors provide real-time data on these parameters, enabling operators to optimize turbine operation, reduce wear and tear, and maximize fuel efficiency. As the deployment of these turbines increases, so does the need for reliable and advanced sensor systems to maintain optimal performance.

- Increased demand for fuel efficiency:

Aeroderivative turbines, often used in power generation and aviation, are highly efficient but require precise control of combustion to maximize fuel efficiency. Sensors monitor parameters like pressure, temperature, and airflow, helping to optimize the combustion process, reduce fuel consumption, and enhance overall efficiency. Fuel is one of the largest operating expenses for industries such as aviation, power generation, and oil and gas. By improving fuel efficiency, aeroderivative sensors help companies lower fuel costs. Sensors provide real-time data that enable more efficient turbine operation, ensuring that only the necessary amount of fuel is used for optimal performance.

- Rising energy demand:

As global energy consumption rises, the need for efficient, flexible, and reliable power generation technologies has grown. Aeroderivative gas turbines are known for their ability to start up quickly, provide backup power, and adjust output based on fluctuating energy demand. Sensors play a critical role in monitoring and optimizing the performance of these turbines, ensuring they meet the increased demand while operating efficiently. With energy consumption patterns becoming more unpredictable, particularly during peak demand periods, aeroderivative turbines are often used to supplement base-load power plants. These turbines are capable of rapidly responding to energy shortfalls, making them essential for grid stability. Sensors help manage and optimize turbine performance during these peak load times by providing real-time data on temperature, pressure, and fuel efficiency, ensuring that turbines operate at maximum capacity when needed.

Request for a sample copy of this report: https://www.imarcgroup.com/aeroderivative-sensor-market-report/requestsample

Aeroderivative Sensor Market Report Segmentation:

Breakup By Sensor Type:

- Temperature Sensor

- Accelerometer

- Pressure Sensor

- Vibration Sensor

- Flame Sensor

- Others

Flame sensor represents the largest segment because it is essential for monitoring combustion in aeroderivative turbines, ensuring safety and optimal fuel efficiency.

Breakup By Service Provider:

- After Market

- OEM

OEM accounts for the majority of the market share as original equipment manufacturers provide integrated, high-quality sensor systems specifically designed for their aeroderivative turbines.

Breakup By End User:

- Industrial

- Marine

Industrial holds the biggest market share due to the widespread use of aeroderivative turbines in industries like power generation, oil and gas, and manufacturing, where efficiency and reliability are critical.

Breakup By Region:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

North America enjoys the leading position in the aeroderivative sensor market owing to its advanced energy infrastructure, large-scale industrial applications, and strong demand for efficient power generation technologies.

Top Aeroderivative Sensor Market Leaders:

The aeroderivative sensor market research report outlines a detailed analysis of the competitive landscape, offering in-depth profiles of major companies. Some of the key players in the market are:

- Bently Nevada (Baker Hughes)

- EthosEnergy

- Meggitt

- KISTLER INSTRUMENT CORP

- Unison

- Conax Technologies

- Auxitrol Weston

Note: If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact US

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1–631–791–1145