In the world of modern manufacturing, CNC (Computer Numerical Control) machining has revolutionized the way parts and components are produced. CNC Machining Parts are widely used across industries such as aerospace, automotive, medical, electronics, and more, thanks to their precision, efficiency, and versatility. This technology has become a cornerstone of manufacturing, enabling the creation of complex and high-quality parts with unmatched accuracy.

What Are CNC Machining Parts?

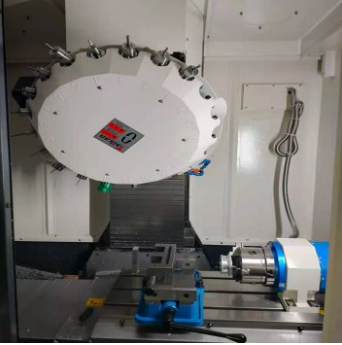

CNC machining parts are components manufactured using CNC machines, which are automated tools controlled by computer programs. These machines follow precise instructions to cut, drill, mill, or shape raw materials like metal, plastic, wood, or composites into finished parts. The process eliminates human error, ensuring consistent quality and tight tolerances.

Key Features of CNC Machining Parts

- High Precision and Accuracy

CNC machines operate with extreme precision, often achieving tolerances as tight as ±0.001 inches. This level of accuracy is critical for industries where even the smallest deviation can impact performance, such as aerospace or medical devices. - Complex Geometries

CNC machining can produce intricate shapes and designs that would be difficult or impossible to achieve with manual machining. From 3D contours to fine details, CNC technology excels at handling complex geometries. - Material Versatility

CNC machines can work with a wide range of materials, including metals (aluminum, steel, titanium), plastics (ABS, PVC, polycarbonate), and even exotic materials like ceramics or composites. This versatility makes CNC machining suitable for diverse applications. - Repeatability and Consistency

Once a design is programmed into the CNC machine, it can produce identical parts repeatedly without variation. This consistency is essential for large-scale production runs. - Efficiency and Speed

CNC machining is faster than traditional manual machining, reducing production time and costs. Automated tool changes and multi-axis capabilities further enhance efficiency. - Customization

CNC machining allows for easy customization, making it ideal for prototyping and low- to medium-volume production. Design changes can be quickly implemented by updating the CNC program.

Applications of CNC Machining Parts

CNC machining parts are used in a wide array of industries and applications, including:

- Aerospace: Engine components, landing gear parts, and structural elements require high precision and durability.

- Automotive: Transmission parts, engine blocks, and custom components benefit from CNC machining’s accuracy and repeatability.

- Medical: Surgical instruments, implants, and diagnostic equipment demand biocompatible materials and tight tolerances.

- Electronics: Housings, connectors, and heat sinks are often produced using CNC machining for their intricate designs.

- Industrial Machinery: Gears, shafts, and valves are commonly manufactured with CNC technology for reliability and performance.

Advantages of CNC Machining Parts

- Superior Quality: CNC machining ensures high-quality finishes and precise dimensions, reducing the need for post-processing.

- Cost-Effective: While initial setup costs can be high, CNC machining becomes cost-effective for large production runs due to its efficiency and reduced waste.

- Scalability: CNC machining is suitable for both prototyping and mass production, making it a flexible solution for businesses of all sizes.

- Reduced Waste: The precision of CNC machining minimizes material waste, contributing to sustainable manufacturing practices.

Choosing the Right CNC Machining Partner

When sourcing CNC machining parts, it’s essential to work with a reliable and experienced manufacturer. Look for a partner with:

- Advanced CNC equipment and technology.

- Expertise in your industry and material requirements.

- A commitment to quality control and certifications (e.g., ISO 9001).

- The ability to provide design support and prototyping services.

Conclusion

CNC machining parts are at the heart of modern manufacturing, offering unparalleled precision, efficiency, and versatility. Whether you’re developing a prototype or scaling up production, CNC machining provides the tools to create high-quality components that meet the demands of today’s industries. By leveraging this advanced technology, businesses can stay competitive, reduce costs, and deliver products that exceed customer expectations.

Investing in CNC machining is not just about producing parts—it’s about driving innovation and achieving excellence in manufacturing.