Handling bulk materials can be a challenging task, especially when it comes to packaging them efficiently. Many businesses that deal with grains, powders, or other loose materials struggle with accuracy, speed, and labor costs when packaging manually. If you’ve been looking for a way to improve your operations, a Bulk Bagger could be the perfect solution.

But what exactly is a Bulk Bagger, and how can it help? Let’s take a deep dive into how this machine can transform your packaging process, saving time and money while improving accuracy.

What is a Bulk Bagger?

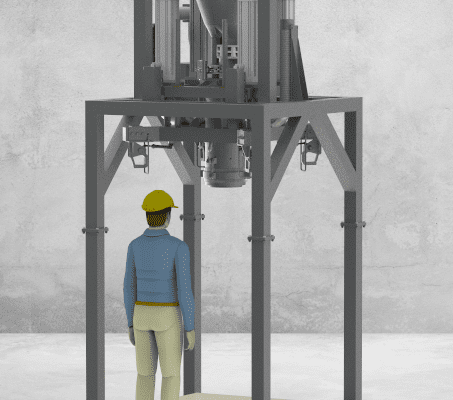

A Bulk Bagger is a machine designed to efficiently fill and weigh bulk bags—also known as super sacks, FIBCs (Flexible Intermediate Bulk Containers), or jumbo bags. Instead of relying on manual labor to scoop, weigh, and fill each bag, this machine automates the entire process, ensuring that each bag is filled with precision and consistency.

Bulk Baggers are used in a variety of industries, including agriculture, food processing, construction, and chemicals. By automating bulk material packaging, businesses can significantly increase efficiency while reducing waste and human error.

Industries That Benefit from a Bulk Bagger

Many businesses rely on Bulk Baggers to make their packaging process faster and more accurate. Here are some of the industries that benefit the most from this technology:

- Agriculture: Farmers and suppliers use Bulk Baggers to package grains, seeds, animal feed, and fertilizers efficiently.

- Construction & Mining: Heavy materials such as sand, gravel, and cement require precise filling to ensure safe transport and proper storage.

- Food Processing: Ingredients like sugar, flour, rice, and coffee beans need to be accurately weighed and packaged to maintain quality and consistency.

- Chemical & Pharmaceutical: Bulk Baggers handle powders, industrial chemicals, and pharmaceutical ingredients, ensuring precise measurement and safe packaging.

- Recycling & Waste Management: Recyclable materials such as plastic pellets, shredded paper, and scrap metal can be easily bagged for storage and transport.

No matter what type of bulk materials your business handles, a Bulk Bagger can help streamline your operations and make your process more efficient.

How Does a Bulk Bagger Work?

A Bulk Bagger operates using a straightforward process that ensures each bag is filled quickly and accurately. Here’s a step-by-step breakdown of how it works:

- Bag Positioning: The operator attaches an empty bulk bag to the machine, which securely holds it in place. Some machines have automated clamps for added stability.

- Material Dispensing: The Bulk Bagger releases the material into the bag using a controlled flow system to prevent overfilling or spillage.

- Weighing System: An integrated scale ensures each bag is filled with the correct weight of material, reducing waste and improving accuracy.

- Vibration & Settling (Optional): Some machines include a vibration feature to help settle the material evenly, reducing excess air pockets.

- Sealing & Removal: Once the bag reaches the target weight, it is sealed and removed, ready for storage or transportation.

This automated process eliminates the inconsistencies of manual bagging and ensures that each bag is properly filled and prepared for transport.

Key Benefits of Using a Bulk Bagger

If you’re still on the fence about whether a Bulk Bagger is right for your business, here are some of the biggest benefits to consider:

1. Increased Efficiency & Productivity

Manually filling bulk bags takes a lot of time and effort. A Bulk Bagger speeds up the process, allowing more bags to be filled in less time, boosting overall productivity.

2. Better Accuracy & Consistency

Weighing materials manually can lead to errors and inconsistencies. A Bulk Bagger ensures that each bag is filled with the exact amount needed, reducing waste and improving product quality.

3. Lower Labor Costs

Automating the bagging process means fewer workers are needed to handle packaging, which can significantly reduce labor costs. Employees can be reassigned to other important tasks, increasing overall efficiency.

4. Reduced Material Waste

Spillage and overfilling are common problems when bagging materials manually. A Bulk Bagger minimizes waste by precisely controlling the flow of materials into each bag.

5. Improved Workplace Safety

Lifting and handling heavy bags manually can lead to injuries. By automating the bagging process, businesses can reduce the risk of workplace injuries and create a safer environment for employees.

6. Versatility for Various Materials

Whether you’re working with fine powders, granules, or large aggregates, a Bulk Bagger can be customized to suit your specific material handling needs.

Choosing the Right Bulk Bagger for Your Business

If you’re considering investing in a Bulk Bagger, here are some key factors to keep in mind:

- Material Type: Make sure the Bulk Bagger you choose is designed to handle the specific material your business processes. Some machines specialize in fine powders, while others are built for heavier materials.

- Bagging Speed: If your production demands are high, look for a machine with fast filling capabilities to meet your requirements.

- Weighing Accuracy: Accuracy is crucial in bulk packaging, so choose a machine with a high-precision weighing system.

- Additional Features: Consider extra features such as dust control, vibration systems, and automatic sealing for improved efficiency.

- Space & Layout Compatibility: Ensure the Bulk Bagger fits well within your production facility and integrates seamlessly with your existing equipment.

The Future of Bulk Bagging Technology

As industries evolve, Bulk Baggers are becoming more advanced with new technologies designed to improve efficiency and automation. Some of the latest innovations include:

- IoT-Enabled Monitoring: Smart Bulk Baggers can connect to the internet, allowing real-time tracking of production data and maintenance needs.

- AI-Powered Precision: Artificial intelligence is being used to optimize weighing accuracy and adjust for variations in material density.

- Sustainable Packaging Solutions: As businesses shift towards eco-friendly practices, Bulk Baggers are being designed to support biodegradable and recyclable bulk bags.

- Compact & Mobile Designs: More businesses are opting for space-saving Bulk Baggers that can be easily moved and integrated into different production lines.

Should You Invest in a Bulk Bagger?

If your business deals with large quantities of material, investing in a Bulk Bagger can be a game-changer. It offers improved efficiency, better accuracy, lower costs, and a safer work environment—all of which contribute to a more productive operation.

Switching to a Bulk Bagger isn’t just about saving time—it’s about optimizing your entire packaging process. Whether you’re in agriculture, construction, food production, or another industry, this machine can help you stay competitive and streamline your operations.

Are you ready to upgrade your packaging process? A Bulk Bagger could be the perfect investment to take your business to the next level.