In the world of manufacturing, tool and die making is an essential process for producing the molds, tools, and dies used in various industries.

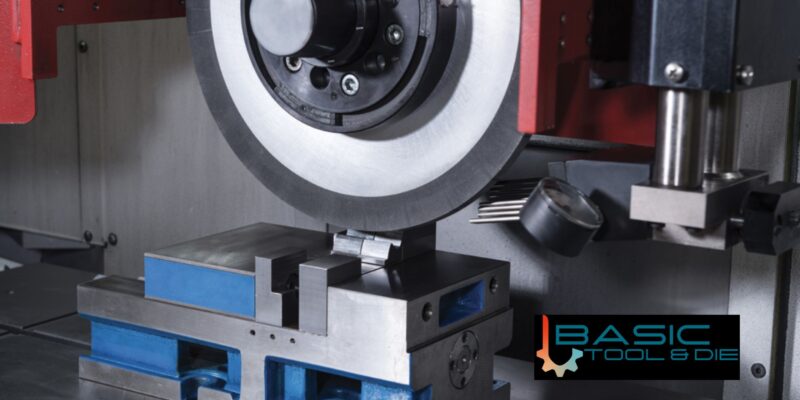

One of the most important technologies used in this field is the EDM machine in Alberta. EDM, which stands for Electrical Discharge Machining, is a process that allows for the creation of complex shapes and designs that would be difficult or impossible to achieve with traditional methods. This process uses electrical sparks to erode metal and shape it with extreme accuracy.

How EDM Machines Work for Tool and Die Making

EDM machines operate by generating electrical discharges between an electrode and the workpiece. These sparks create a high level of heat that melts and erodes the material. The material is then flushed away, leaving a highly detailed and accurate cut. The two most common types of EDM used in tool and die making are wire EDM and sinker EDM.

- Wire EDM: This type of EDM machine uses a thin, electrically charged wire to cut through the material. It is perfect for cutting intricate shapes and tight tolerances, which are essential in tool and die making. Wire EDM is often used for creating molds and dies that require very precise features.

- Sinker EDM: In sinker EDM, the electrode is shaped like the desired final product and is lowered into the workpiece. The electrical discharges then erode the material, creating the exact shape. This is often used for more complex shapes where wire EDM may not be as effective.

Benefits of Using EDM Machines in Tool and Die Making

- High Accuracy

One of the key reasons EDM machines are used in tool and die making is their ability to achieve high levels of accuracy. The electrical discharge process allows manufacturers to create precise and intricate designs, ensuring that the tools and dies will fit perfectly and function as intended. - Complex Shapes and Features

EDM machines can produce shapes that would be impossible to create using traditional cutting methods. This is particularly useful when making molds for casting or dies for stamping. These machines are capable of creating undercuts, sharp corners, and fine details without the need for additional tools or processes. - Works on Hard Materials

EDM machines can easily work with hard metals, including alloys that are typically difficult to machine with conventional methods. This is particularly important in tool and die making, as many of the materials used for tools and molds must be extremely durable and resistant to wear and tear. - No Mechanical Stress

Unlike traditional machining methods, EDM does not involve physical cutting or mechanical pressure on the material. This means that delicate or thin materials can be machined without the risk of distortion or damage, which is crucial in tool and die making, where the integrity of the material is important.

Applications of EDM in Tool and Die Making

EDM machines are used to create a wide range of tool and die products, including:

- Injection Molds: EDM is used to create the complex cavities in injection molds, ensuring they can produce parts with intricate shapes and fine details.

- Progressive Dies: These dies are used to shape metal parts in a continuous process. EDM machines can be used to create the precision cuts required for each stage of the die.

- Prototype Tools: When creating prototype tools, EDM machines allow manufacturers to quickly make changes and adjustments to the design without the need for costly modifications to traditional tools.

- Punch and Die Sets: EDM is also used to create punch and die sets for stamping and cutting metal. The high level of detail and accuracy makes these tools ideal for use in industries like automotive and aerospace manufacturing.

The Future of EDM Machines in Tool and Die Making

The future of EDM machines in tool and die making looks promising. As technology continues to evolve, newer EDM machines are being developed with even more advanced features. These machines are becoming faster, more efficient, and capable of producing even more complex shapes with greater accuracy. Manufacturers in Alberta and beyond are increasingly turning to EDM machines to meet the demands of modern tool and die making.

Takeaways

While EDM machine in Alberta is essential in creating high-quality tools and dies, integrating it with other technologies like the CNC sheet metal bending machine can further improve the manufacturing process. CNC bending machines offer additional capabilities in shaping metal, allowing for precise bending, cutting, and forming of materials. By combining EDM with other advanced machinery, manufacturers can optimize production and achieve greater results in tool and die making.