Introduction to Industrial Model Making

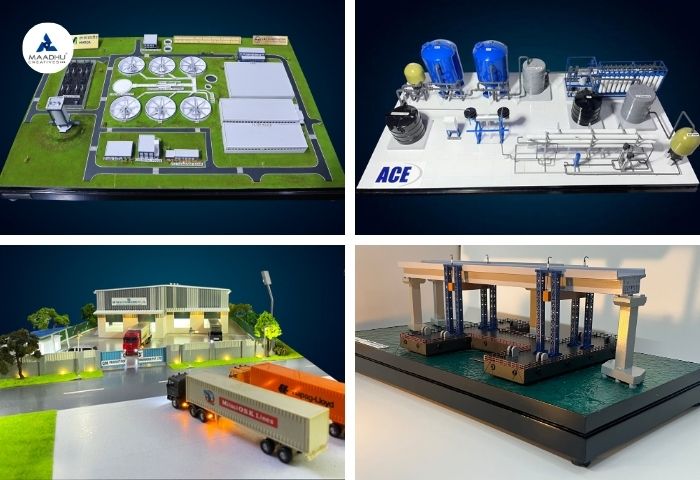

Industrial model making is a crucial discipline across various sectors, including architecture, engineering, and manufacturing. This practice involves creating tangible or digital representations of products, systems, or structures at a scaled level. Whether through physical models or virtual simulations, model making serves as an essential tool for visualizing, testing, and communicating design concepts. As industries evolve, the significance of model making grows, allowing designers and engineers to turn abstract ideas into concrete forms.

Advantages of Industrial Model Making

Enhanced Visualization

One of the primary benefits of industrial model-making is the ability to enhance visualization. Traditional hand-drawn sketches or digital images often fall short in conveying complex ideas. Models provide a three-dimensional representation, enabling stakeholders to grasp the look and functionality of the final product. This clarity helps teams communicate effectively and align their understanding of the project.

Improved Communication

Models serve as a bridge for communication among team members, clients, and investors. By presenting a physical model, designers can illustrate their vision more effectively, minimizing misunderstandings and ensuring everyone is aligned with the project’s objectives. This shared understanding fosters collaboration and drives the project forward.

Design Validation

Creating a model allows designers to validate their concepts before moving to production. This process helps identify potential issues early on, reducing the risk of delays and resource wastage later in the production cycle. By testing and refining designs through models, companies can ensure higher quality and reliability in their final products.

Market Testing

Industrial models can be invaluable for market testing. Companies can gather consumer feedback on prototypes by presenting them to focus groups or stakeholders. This feedback is crucial for making necessary adjustments before a product launch, increasing the likelihood of market success.

Cost Efficiency

While the initial investment in model making can be substantial, the long-term savings often outweigh these costs. Identifying flaws early in the design process can prevent costly modifications during mass production. Thus, effective model making contributes to overall cost efficiency in product development.

Educational Tool

In the educational sphere, industrial model making serves as a powerful learning tool. It allows students in fields such as engineering, architecture, and design to engage with complex concepts in a hands-on manner. By interacting with models, students can better grasp theoretical ideas, making learning more effective and enjoyable.

Key Aspects of Industrial Model Making

Materials and Techniques

The choice of materials for industrial models varies widely, including wood, plastic, metal, and foam. The selection depends on the application and the level of detail required. Various techniques are employed to create precise and intricate models, such as 3D printing, CNC machining, and traditional handcrafting methods.

Scale and Detail

Models can differ significantly in scale and detail. For instance, architectural models might represent entire buildings, while product prototypes can be much smaller and focused on specific features. The project requirements and target audience heavily influence these decisions.

Collaboration

Industrial model making is inherently collaborative. Effective communication and collaboration among designers, engineers, and clients are essential to ensuring that the model accurately reflects the desired design. This teamwork not only leads to successful outcomes but also sparks innovation and creativity throughout the design process.

Rapid Prototyping

Advancements in digital technology have revolutionized industrial model making, particularly through rapid prototyping methods like 3D printing. These technologies enable designers to produce and iterate models at an accelerated pace, allowing for quick conceptualization and refinement of ideas.

Sustainability

As industries increasingly prioritize sustainability, model makers are adapting their practices to align with these values. This includes using eco-friendly materials and minimizing waste throughout the modeling process. By focusing on sustainable practices, model makers contribute to broader environmental goals.

Conclusion

Industrial model-making serves as a vital link between concept and reality. It enhances visualization, fosters effective communication, and aids in design validation, making it essential across various industries. As technology continues to advance, the possibilities for model making will only expand, driving innovation in fields like architecture, engineering, and product design. Embracing this craft is key to developing high-quality, market-ready products.

FAQs

1. What benefits does industrial model making provide to businesses?

Industrial model making enhances product design, improves communication among stakeholders, reduces mass production costs, and validates concepts before full-scale production. Ultimately, better-designed products lead to increased market success.

2. How long does it typically take to create an industrial model?

The time required to develop an industrial model varies based on design complexity and material choice. Simple models may take just a few days, while intricate designs can take weeks or even months to complete.

3. What skills are essential for successful industrial model-making?

Key skills for industrial model making include proficiency in design software (such as CAD), manual dexterity, attention to detail, knowledge of materials and manufacturing processes, creativity, and problem-solving abilities.