Introduction

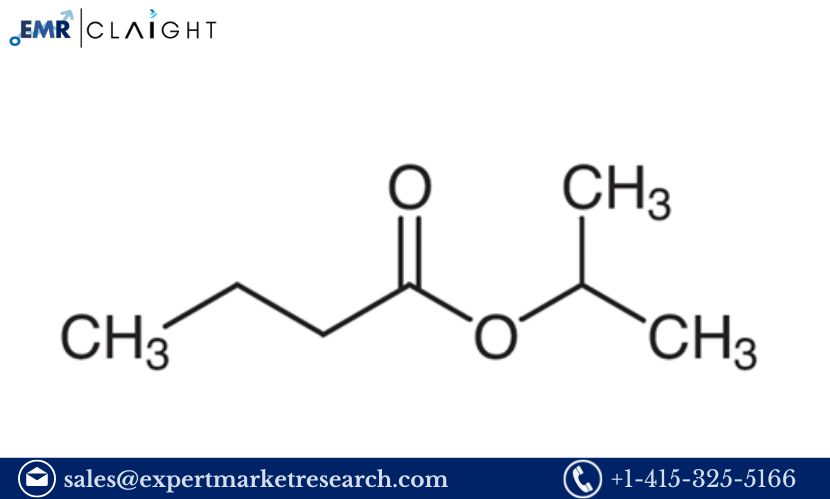

The bedding material fabric manufacturing industry plays a crucial role in meeting the growing demand for comfortable and high-quality bedding products. This comprehensive Isopropyl Butyrate Manufacturing Plant Project Report on the bedding material fabric manufacturing plant aims to provide detailed insights into the processes involved, market dynamics, and essential considerations for entrepreneurs and investors. Understanding the scope of this industry is vital for anyone looking to venture into this business, as it encompasses various aspects, including material selection, production processes, and market trends.

Overview of the Bedding Material Fabric Manufacturing Industry

The bedding material fabric manufacturing industry focuses on producing fabrics used in various bedding products, including mattresses, bed sheets, pillowcases, and comforters. The demand for bedding materials has seen significant growth due to the increasing awareness of sleep health, coupled with rising disposable incomes and lifestyle changes. As consumers prioritize comfort and quality in their sleep environments, manufacturers must stay updated on the latest trends and technologies.

Definition of Bedding Materials

Bedding materials refer to the fabrics and textiles used in the production of bedding products. These materials can vary significantly in terms of texture, durability, and functionality. Common types of bedding materials include:

- Cotton: Known for its softness and breathability, cotton is a popular choice for sheets and pillowcases.

- Polyester: This synthetic fabric is often used for its durability and resistance to wrinkles.

- Bamboo: An eco-friendly option, bamboo fabric is gaining popularity due to its moisture-wicking properties and sustainability.

- Memory Foam: Used primarily in mattresses, memory foam offers excellent support and comfort by conforming to the body’s shape.

Get a Free Sample Report with Table of Contents @

Manufacturing Process of Bedding Material Fabric

The manufacturing process of bedding materials involves several steps, from raw material selection to final product finishing. Here’s a general overview of the steps involved:

1. Raw Material Selection

Selecting the right raw materials is essential for producing high-quality bedding fabrics. Manufacturers typically source materials based on desired characteristics, such as comfort, durability, and environmental impact. The choice of material also affects the production process, as different fabrics may require specific treatments or techniques.

2. Fabric Production

Once the raw materials are selected, the production process begins. This stage can include:

- Spinning: Fibers are spun into yarns, which form the basis of the fabric.

- Weaving or Knitting: The yarns are woven or knitted together to create fabric. The weaving method used can affect the fabric’s texture and strength.

- Finishing: Fabrics undergo various finishing processes, such as dyeing, printing, and applying treatments for stain resistance or softness.

3. Quality Control

Quality control is a crucial part of the manufacturing process. Fabrics are tested for various characteristics, including colorfastness, shrinkage, and strength. Ensuring that products meet industry standards is vital for maintaining customer satisfaction and brand reputation.

4. Cutting and Sewing

After quality control, the fabric is cut into specific sizes for various bedding products. Skilled workers then sew the pieces together to create finished products like sheets, pillowcases, and comforters. Automation may be employed in this stage to enhance efficiency and precision.

5. Packaging and Distribution

Once the products are finished, they are packaged for shipment. Proper packaging ensures that the bedding materials reach consumers in excellent condition. Distribution strategies may include partnerships with retailers, online sales, or direct-to-consumer models.

Production Cost Report

While specific numerical values are avoided in this report, understanding the various costs associated with running a bedding material fabric manufacturing plant is essential for potential investors. Key factors influencing production costs include:

- Raw Material Costs: The price of cotton, polyester, or other materials can significantly impact overall expenses. Market fluctuations may affect sourcing strategies.

- Labor Costs: Skilled labor is required for various manufacturing processes, and wages can vary based on location and expertise.

- Overhead Expenses: These include utilities, rent, and maintenance of machinery. Efficient management of these costs can improve profitability.

- Marketing and Distribution Costs: Effective marketing strategies and distribution channels are essential for reaching target consumers and building brand awareness.

Market Trends and Opportunities

The bedding material fabric manufacturing industry is evolving, driven by changing consumer preferences and advancements in technology. Here are some notable trends:

Sustainability

Consumers are increasingly seeking eco-friendly products, driving the demand for sustainable bedding materials. Manufacturers are adopting environmentally friendly practices, such as using organic cotton or recycled materials, to appeal to this growing market segment.

Technological Advancements

Innovation in manufacturing technology, such as automation and digital printing, is reshaping the industry. These advancements enhance production efficiency and allow for greater customization of products.

Health and Wellness

As consumers become more health-conscious, there is a rising demand for bedding materials that promote better sleep quality. Fabrics that offer moisture-wicking properties, hypoallergenic features, and temperature regulation are gaining popularity.

Challenges in the Industry

Despite the growth potential, the bedding material fabric manufacturing industry faces several challenges:

Competition

The industry is highly competitive, with numerous players vying for market share. Differentiating products through quality, design, and sustainability is crucial for success.

Supply Chain Disruptions

Global events can disrupt supply chains, impacting the availability of raw materials. Manufacturers must develop robust supply chain strategies to mitigate these risks.

Regulatory Compliance

Adhering to regulations regarding safety, environmental standards, and labor practices can be complex. Manufacturers must stay informed about compliance requirements to avoid legal issues.

Future Prospects

The future of the bedding material fabric manufacturing industry looks promising. With continued advancements in technology and growing consumer demand for quality and sustainability, manufacturers are well-positioned for growth. Entrepreneurs entering this market should focus on innovation, quality, and consumer preferences to capitalize on emerging opportunities.

FAQ

What types of materials are commonly used in bedding fabric manufacturing?

Common materials include cotton, polyester, bamboo, and memory foam, each offering unique benefits and characteristics.

How can manufacturers ensure the quality of their bedding materials?

Implementing strict quality control measures during production, including testing for colorfastness and strength, can help maintain high standards.

What are the key trends shaping the bedding material fabric manufacturing industry?

Current trends include a focus on sustainability, technological advancements in manufacturing processes, and increased consumer interest in health and wellness.

What challenges do bedding fabric manufacturers face?

Manufacturers contend with competition, supply chain disruptions, and the need to comply with various regulations.

How can I enter the bedding material fabric manufacturing business?

Entering this business requires a thorough understanding of the market, sourcing quality materials, implementing efficient production processes, and developing effective marketing strategies.

Related Reports

https://www.expertmarketresearch.com/reports/incident-and-emergency-management-market

https://www.expertmarketresearch.com/articles/top-digital-marketing-companies

https://www.expertmarketresearch.com/reports/plastic-additives-market

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au