Hydraulic hoses play a vital role in heavy machinery and industrial systems, transferring hydraulic fluid to ensure seamless operations. When a hydraulic hose fails, it can lead to serious downtime and even safety hazards. Knowing how to properly maintain, diagnose, and repair these hoses is essential for industries that rely on hydraulic systems.

Understanding Hydraulic Hoses Hydraulic hoses are specialized tubes designed to carry hydraulic fluids under high pressure. These hoses are reinforced with steel or braided fabric, making them robust and capable of handling extreme conditions. However, they are not invincible and can wear out due to factors like external damage, aging, or improper installation. Common industries that rely on hydraulic hoses include construction, manufacturing, agriculture, and automotive sectors.

Common Causes of Hydraulic Hose Failure Several factors contribute to the failure of hydraulic hoses:

-

Incorrect Installation: Poor routing of hoses can lead to unnecessary strain.

-

High Temperatures: Excessive heat can cause the rubber to harden and crack.

-

Abrasion: Frequent rubbing against metal parts or surfaces erodes the hose’s outer layer.

-

Pressure Surges: Sudden pressure changes can rupture hoses that aren’t rated for the system’s specifications.

Tools Needed for Hydraulic Hose Repair If a hose is damaged, you may need several key tools for a successful repair:

-

Wrenches – For loosening or tightening hose connections.

-

Crimping Machine – Essential for attaching new fittings to a replacement hose.

-

Hydraulic Fluid – For refilling the system after the repair is complete.

-

Cutting Tool – To remove the damaged section of the hose.

-

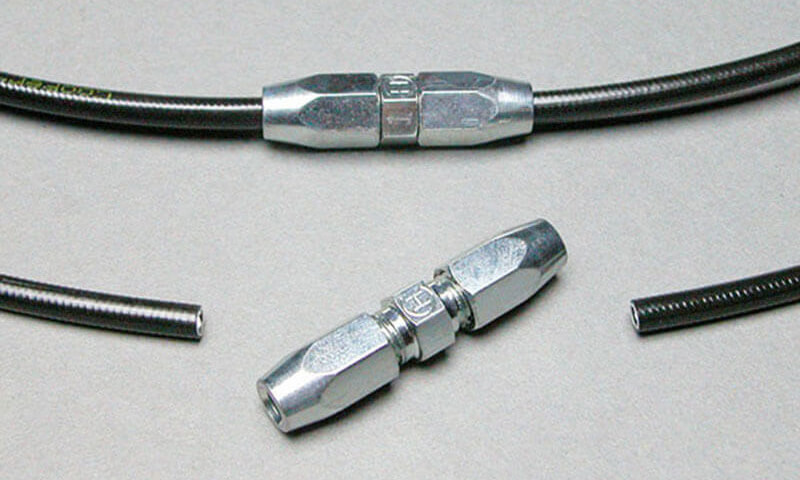

Fittings and Adaptors – To ensure a secure connection between hoses.

Steps to Repair a Hydraulic Hose

-

Identify the Problem: Inspect the entire length of the hose for visible signs of damage, from cracks to leaks.

-

Release Pressure: Always release any pressure from the hydraulic system before removing the hose. Failure to do so can be dangerous.

-

Remove the Damaged Hose: Use a wrench to carefully disconnect the hose from the fittings.

-

Cut and Crimp the New Hose: If a section of the hose is salvageable, cut off the damaged portion. Otherwise, use a new hose and crimp it with the correct fittings.

-

Reattach and Test: Once the hose is repaired, reattach it to the hydraulic system and test it under low pressure to ensure everything is functioning correctly.

Preventive Maintenance Tips

-

Regular Inspection: A visual inspection can often identify wear and tear before it becomes a major problem.

-

Proper Routing: Ensure hoses are routed properly to avoid excessive twisting or bending.

-

Use Protective Sleeves: Abrasion sleeves can prevent hoses from wearing out due to constant rubbing against machine parts.

-

Check System Pressure: Ensure the hose you’re using is rated for your system’s maximum pressure to avoid unexpected bursts.

-

Replace on Schedule: Hydraulic hoses have a finite lifespan, and replacing them on a preventive maintenance schedule can save you costly repairs.

When to Call a Professional While basic hose repairs can be handled in-house, there are situations where you’ll need a professional service. If a hose burst leads to contamination in the system, or if you’re unsure of the repair steps, hiring an expert ensures your system’s integrity.

Inflex Hydraulics – Your Hydraulic Hose Repair Partner For industries across sectors like construction, marine, and automotive, having a reliable partner for hydraulic hose repair is essential. Inflex Hydraulics, based in Dubai, offers professional services, including mobile hose repair vans that bring expert solutions to your location. Their experienced team handles everything from quick on-site repairs to custom hydraulic solutions tailored to your system’s needs.

Inflex Hydraulics provides specialized services to minimize downtime and ensure operational efficiency. With their hydraulic hose van service, you can have your hoses repaired or replaced on-site, helping you avoid unnecessary transportation costs and delays. The team is equipped with an extensive inventory of hoses, fittings, and adapters for various applications, ensuring they are ready to handle any situation that arises.

Conclusion Hydraulic hose repair is a critical aspect of maintaining the efficiency and safety of your machinery. By staying aware of the signs of wear, conducting routine inspections, and acting quickly when issues arise, you can significantly extend the lifespan of your hoses and reduce costly downtime. Whether you’re handling repairs in-house or calling in a professional service like Inflex Hydraulics, ensuring that your hydraulic system remains in top condition is vital to keeping your operations running smoothly.