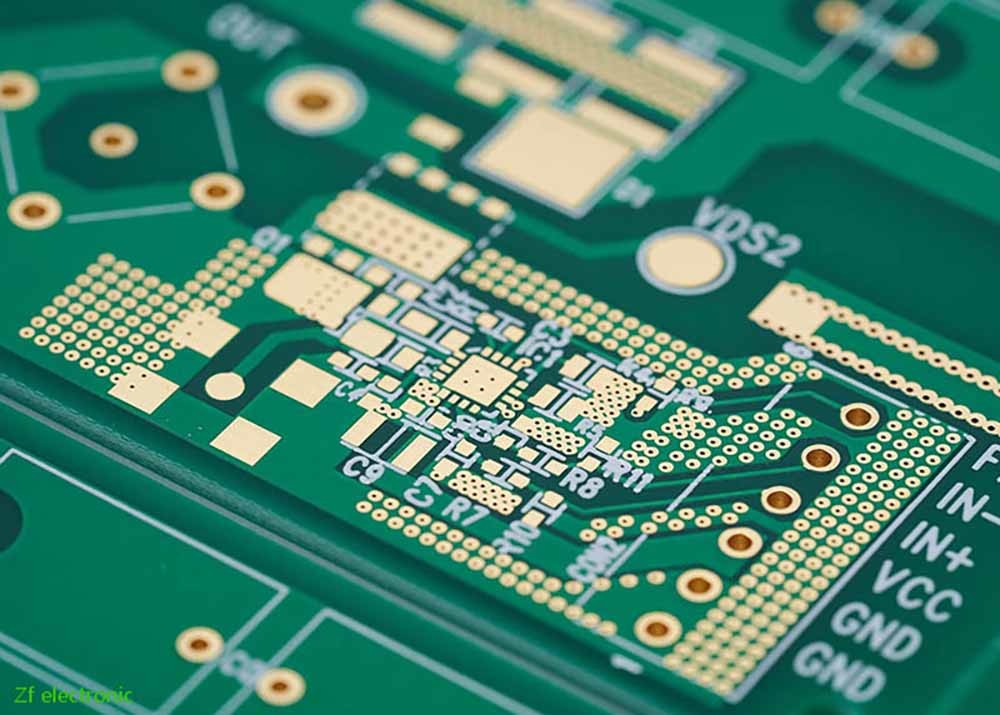

In the world of electronics, the backbone of innovation is hidden within the intricate, delicate world of Printed Circuit Boards (PCBs). PCBs are the foundation of nearly all electronic devices, from smartphones to advanced medical equipment. Behind each PCB lies the skilled craftsmanship of PCB assembly manufacturers, a sector that has seen explosive growth in recent decades, particularly in China. The story of China’s dominance in the PCB assembly industry is one of innovation, global collaboration, and a relentless pursuit of precision.

The Birth of the PCB: A Revolution in Electronics

Before we delve into the success of PCB assembly manufacturers in China, it’s important to understand the significance of PCBs themselves. PCBs were first developed in the early 20th century as a means of connecting electronic components more efficiently. Instead of using bulky wires, manufacturers could embed conductive tracks into a thin board, allowing electrical signals to flow seamlessly between components.

This breakthrough technology laid the foundation for modern electronics. By the 1950s, PCBs were being used in radios, televisions, and computers, but it wasn’t until the advent of personal electronics in the late 20th century that the demand for PCBs truly skyrocketed.

The Emergence of Chinese PCB Assembly Manufacturers

In the 1980s and 1990s, China began to establish itself as a manufacturing powerhouse. The country’s low labor costs, coupled with favorable government policies, made it an attractive destination for foreign companies looking to outsource production. As global demand for electronics surged, China quickly became a hub for PCB assembly, which involves mounting electronic components onto the board and ensuring that they function as intended.

Chinese PCB assembly manufacturers rapidly gained a reputation for their ability to produce high-quality products at competitive prices. One of the pioneers in this industry was Shanghai-based PCBTech, a company founded in 1992 by a group of engineers with a passion for precision engineering. PCBTech started as a small operation, assembling basic circuit boards for local electronics companies. However, as demand grew, so did their ambition.

Recognizing the global potential of their business, PCBTech invested heavily in state-of-the-art machinery and training for their employees. By the early 2000s, they were not only assembling PCBs for local companies but also exporting to tech giants in the United States, Europe, and Japan.

Innovation Drives Growth

What set Chinese PCB assembly manufacturers apart from their competitors was their willingness to embrace innovation. Companies like PCBTech quickly adopted surface-mount technology (SMT), which allowed for smaller, more complex components to be mounted onto the boards with incredible precision. This was a game-changer for the electronics industry, as it allowed for the production of more compact and powerful devices.

In addition to SMT, Chinese manufacturers also embraced automation. By incorporating robotic arms and automated optical inspection systems into their assembly lines, they were able to produce PCBs faster and with fewer errors. This commitment to innovation enabled Chinese companies to keep up with the ever-increasing demand for more sophisticated electronic devices.

Another key factor in the success of Chinese PCB assembly manufacturers was their focus on customization. Unlike some of their competitors, who offered standardized products, Chinese manufacturers were willing to work closely with their clients to design and produce custom PCBs tailored to specific needs. This flexibility made them a favorite among tech startups and established companies alike, who often required unique solutions for their cutting-edge products.

The Role of Quality Control

In the highly competitive world of electronics, quality is paramount. Even the smallest defect in a PCB can lead to device failure, which is why PCB assembly manufacturers in China have made quality control a top priority. At PCBTech, for example, every board undergoes rigorous testing before it leaves the factory.

“We understand that our customers’ reputations are on the line,” says Li Jun, the company’s quality control manager. “A faulty PCB can cost them millions in lost sales, so we take quality control very seriously.”

To ensure that each board meets the highest standards, PCBTech employs a combination of automated testing and manual inspections. Automated systems check for electrical continuity, ensuring that signals are flowing correctly between components. Meanwhile, trained technicians visually inspect each board for any physical defects, such as misaligned components or soldering issues.

In addition to their in-house testing, many Chinese manufacturers also adhere to international quality standards, such as ISO 9001 and IPC-A-610, which provide guidelines for the design, assembly, and testing of PCBs. By adhering to these standards, Chinese manufacturers have been able to build trust with clients around the world.

Global Collaboration and Expansion

One of the keys to the success of Chinese PCB assembly manufacturers has been their ability to collaborate with international partners. Many of these manufacturers work closely with foreign tech companies, helping them to design and produce custom PCBs for a wide range of applications, from consumer electronics to industrial automation.

Companies like PCBTech have also established partnerships with foreign universities and research institutions, allowing them to stay at the forefront of technological advancements. For example, in 2015, PCBTech began collaborating with a leading American university on a project to develop flexible PCBs that could be used in wearable technology.

These collaborations have not only helped Chinese manufacturers to stay competitive but have also allowed them to expand their global reach. Today, China is home to some of the best PCB assembly manufacturers in the world, serving clients in over 100 countries.

Challenges on the Horizon

Despite their success, Chinese PCB assembly manufacturers face several challenges. One of the biggest is the rising cost of labor in China, which has led some companies to relocate their operations to other countries, such as Vietnam and India. Additionally, the trade tensions between China and the United States have created uncertainty for manufacturers who rely on exports to American tech companies.

To stay competitive, Chinese manufacturers are increasingly focusing on automation and advanced manufacturing techniques. By reducing their reliance on manual labor, they can keep costs down while maintaining high levels of precision and quality. Many are also investing in green manufacturing practices, such as using lead-free solder and reducing waste in their production processes.

The Future of PCB Assembly Manufacturers in China

Looking to the future, it’s clear that PCB assembly manufacturers in China will continue to play a crucial role in the global electronics industry. As technology continues to evolve, so too will the demands placed on PCBs. With the rise of 5G, artificial intelligence, and the Internet of Things (IoT), there will be an increasing need for more powerful, smaller, and more energy-efficient PCBs.

Chinese manufacturers are already gearing up to meet these challenges. Companies like PCBTech are investing heavily in research and development, exploring new materials and manufacturing techniques to create the next generation of PCBs. At the same time, they are expanding their global footprint, opening new factories and research centers in key markets around the world.

In the end, the story of China’s PCB assembly manufacturers is one of resilience, adaptability, and a relentless pursuit of excellence. From humble beginnings, they have grown into global leaders, shaping the future of electronics one board at a time. As long as there is a demand for cutting-edge technology, Chinese PCB manufacturers will be there, pushing the boundaries of what’s possible.

Conclusion: The Best in the Business

Today, the best PCB assembly manufacturers are not just producing boards—they are innovating for the future. Through a combination of precision engineering, quality control, and a focus on global collaboration, these manufacturers continue to lead the way in the ever-evolving world of electronics. As the digital age marches forward, Chinese PCB manufacturers are poised to remain at the forefront of technological advancements, ensuring that the world’s most advanced devices continue to function flawlessly.