Polyethylene (PE) film is one of the most commonly used materials in the world due to its versatility, durability, and cost-effectiveness. Whether it’s used for plastic film packaging, agricultural applications, or industrial purposes, PE film is a staple in various industries. This article will explore the various types of PE film, its benefits, and how it is used in packaging and other applications. Additionally, we will highlight the role of PE film suppliers and how they contribute to the availability of this material in the market. By understanding the unique properties and broad uses of Pulkit Plastic Products, businesses and consumers can make informed decisions regarding their packaging and material needs.

What is PE Film and How is it Made?

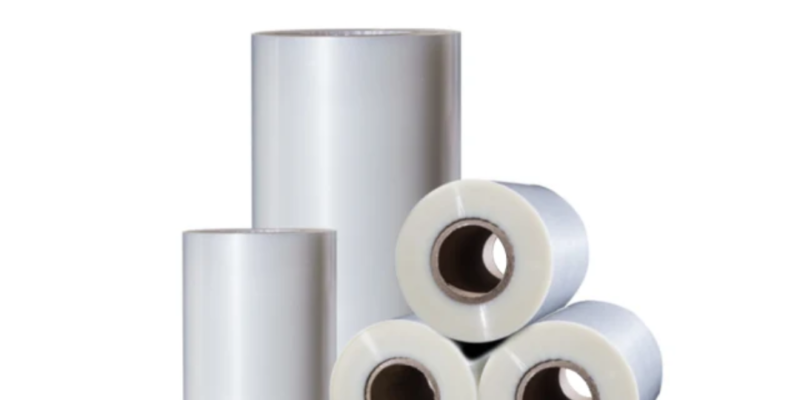

PE film is a thin, flexible material derived from polyethylene, a widely used thermoplastic polymer. The film is created through a process called extrusion, where molten polyethylene is passed through a flat die or a blown film process to form a thin, continuous sheet of film. Depending on the type of polyethylene used, the film can have different properties such as strength, clarity, and flexibility.

There are two primary types of PE film: low-density polyethylene (LDPE) and high-density polyethylene (HDPE). LDPE is softer, more flexible, and more transparent, making it ideal for consumer packaging applications. HDPE, on the other hand, is stiffer and more rigid, providing better strength and resistance to impact and punctures.

PE film material can be produced in various thicknesses, widths, and lengths, and can be treated or coated for specific purposes such as moisture resistance, UV protection, or printing. This versatility makes it highly suitable for a wide range of applications, from packaging to agriculture and construction.

Types of PE Film and Their Uses

There are several types of Plastic film packaging available in the market, each suited to different applications based on their properties. Understanding these types can help businesses choose the right material for their specific needs.

- Stretch Film: Stretch PE film is commonly used in packaging for securing and bundling goods. It has high elongation properties, which allow it to stretch and cling tightly to products, keeping them safe during transportation. It’s often used for pallet wrapping and securing products that need to stay together during shipment.

- Shrink Film: Unlike stretch film, shrink PE film shrinks when heat is applied. It’s commonly used for wrapping products in retail environments, creating a tight and tamper-evident seal. Shrink film is popular in food packaging, where it helps preserve freshness by providing a secure and protective covering.

- Polyethylene Terephthalate (PET) Film: Although not strictly made from polyethylene, PET films are commonly used in combination with PE film for applications like flexible packaging. PET films offer excellent clarity and strength, making them ideal for packaging high-value products such as electronics or food.

- Blown Film: Blown PE film is created using a process that produces a tube of film that is expanded by air. This type of film is often used for creating bags, liners, and heavy-duty packaging materials. Blown PE film provides superior strength and puncture resistance, making it ideal for bulk packaging and industrial applications.

The Benefits of Using PE Film

PE film offers numerous benefits that have contributed to its widespread use across industries. Some of the key advantages of PE film material include:

- Durability: PE film is known for its resilience, as it is resistant to tearing, puncturing, and abrasion. This makes it ideal for both industrial applications and consumer products that require strong and reliable packaging.

- Lightweight: Despite its strength, PE film is incredibly lightweight, which makes it an efficient material for packaging and shipping. Its lightweight nature reduces transportation costs, which is especially beneficial for businesses looking to optimize their logistics operations.

- Moisture Resistance: PE film is highly resistant to moisture, making it ideal for packaging products that need protection from water, humidity, or rain. This makes it widely used in food packaging, pharmaceuticals, and agricultural applications.

- Cost-Effectiveness: Compared to other materials like metal, glass, or paper, PE film is an affordable option for packaging. Its relatively low production cost allows businesses to keep packaging expenses low, particularly when large quantities are needed.

- Recyclability: PE film is recyclable, and many companies and municipalities have set up systems to recycle polyethylene products. This environmental benefit makes it a sustainable choice for businesses aiming to reduce their carbon footprint and minimize waste.

PE Film in Plastic Film Packaging

One of the most prominent applications of PE film is in plastic film packaging. Packaging is a key industry where PE film excels due to its ability to offer protection, preserve product integrity, and enhance shelf appeal.

- Food Packaging: PE film is widely used in the food industry due to its excellent moisture resistance and ability to provide airtight seals. Stretch film is often used to wrap fresh produce, while shrink film is employed for retail packaging of snacks, beverages, and frozen foods. The material helps extend the shelf life of perishable items by protecting them from contamination.

- Industrial Packaging: In industries where bulk products need to be packaged and shipped, PE film is often used for pallet wrapping and securing goods. Blown PE film provides strength and durability, ensuring that items remain intact during storage and transport.

- Retail Packaging: Retailers often use PE film to package items such as electronics, clothing, and consumer goods. Shrink film, in particular, is used for creating tamper-evident packaging that increases consumer confidence in product integrity.

Plastic film packaging made from PE is not only practical but also customizable. Businesses can print logos, branding, and product information directly onto the film, which increases visibility and aids in marketing efforts.

PE Film in Agriculture

Another significant use of PE film material, where it is used to create protective barriers for crops, improve yields, and optimize growing conditions.

- Greenhouse Films: PE film is used as a covering material for greenhouses due to its excellent light transmission and ability to provide a controlled environment for plant growth. Greenhouse PE film can be treated to provide UV protection, helping to protect plants from harmful sunlight while ensuring adequate light penetration.

- Mulching Films: PE film is also used in agriculture for mulching, which helps to prevent weed growth, conserve moisture, and improve soil temperature. Mulching films are often used in row crops, vineyards, and gardens to enhance plant growth and yield.

- Silage Covers: Farmers use PE film as covers for silage, a fermented fodder made from green foliage. The film helps to preserve the nutritional value of the silage by providing a waterproof barrier that prevents contamination and spoilage.

These applications highlight the versatility of PE film in the agricultural sector, contributing to both higher productivity and more sustainable farming practices.

The Role of PE Film Suppliers in the Market

The demand for PE film has led to the rise of specialized PE film suppliers who play a crucial role in ensuring that industries have access to this valuable material. Suppliers source PE film from manufacturers and distribute it to businesses in various sectors, including food, agriculture, packaging, and construction.

A reliable PE film supplier offers a wide range of products tailored to meet the specific needs of different industries. Suppliers also ensure timely delivery, quality assurance, and customer support to help businesses source the right type of PE film for their applications. Many suppliers offer custom sizes, thicknesses, and treatments, allowing customers to obtain film that meets their specific requirements.

As businesses increasingly prioritize sustainability, many PE film suppliers are also focusing on offering eco-friendly options, such as biodegradable or recyclable PE films, to help their customers meet environmental goals.

Conclusion

PE film is a highly versatile and cost-effective material used in a wide array of applications, from plastic film packaging to agriculture and industrial uses. Its combination of durability, moisture resistance, and recyclability makes it an excellent choice for businesses across various sectors. As the demand for sustainable and high-performance materials continues to rise, PE film suppliers play an essential role in ensuring that companies have access to the right film material for their needs. Whether it’s for packaging, agriculture, or beyond, PE film remains a staple in industries around the world.

Frequently Asked Questions

Q1. What is the difference between LDPE and HDPE films?

LDPE (Low-Density Polyethylene) is softer, more flexible, and more transparent, while HDPE (High-Density Polyethylene) is stiffer, stronger, and more resistant to punctures. LDPE is often used for consumer packaging, while HDPE is better for industrial and heavy-duty applications.

Q2. Is PE film recyclable?

Yes, PE film is recyclable, and many municipalities have recycling programs in place to handle polyethylene products. Recycled PE film can be used in the production of new products, reducing environmental waste.

Q3. Can PE film be used for food packaging?

Absolutely! PE film is widely used in food packaging due to its moisture resistance, ability to provide airtight seals, and capacity to protect food from contamination. Shrink films and stretch films are commonly used in food packaging.

Q4. How do I choose the right type of PE film for my needs?

Choosing the right PE film depends on the application. Consider factors such as the required strength, flexibility, moisture resistance, and whether customization (e.g., printing or coating) is needed. A PE film supplier can help you choose the best material for your needs.