When considering options for driveways, many homeowners and property developers are increasingly turning to resin bound driveway. This innovative surfacing solution not only enhances the aesthetic appeal of a property but also offers various practical benefits. In this article, we will explore what a resin bound driveway is, its components, installation process, advantages, maintenance requirements, and considerations to keep in mind before choosing this option.

Understanding Resin Bound Driveways

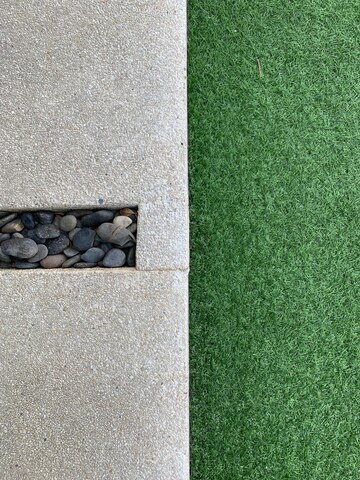

A resin bound driveway consists of a mixture of natural aggregates (such as stones and gravel) bound together with a clear resin. The result is a smooth, durable, and visually appealing surface that can be used for driveways, paths, and patios. Unlike traditional driveways that often rely on concrete or asphalt, resin bound driveways provide a modern and flexible alternative.

The resin used in these driveways is typically made from a combination of epoxy or polyurethane. This formulation allows for a variety of finishes and colors, enabling homeowners to create a customized look that complements their property. The aggregates can be chosen based on size, shape, and color, making it possible to achieve a unique appearance that stands out.

Components of a Resin Bound Driveway

The primary components of a resin bound driveway include:

-

Aggregates: The stones or gravel used in the mixture can vary widely. Homeowners can choose from a range of colors and sizes to create a bespoke finish. The aggregates are essential for the visual appeal and functionality of the driveway.

-

Resin: The resin acts as a binder, holding the aggregates together and providing a solid, cohesive surface. It is crucial that the right type of resin is selected for optimal durability and performance.

-

Base Layer: A solid and stable base is vital for the longevity of a resin bound driveway. Typically, this base is made of concrete or asphalt, providing a strong foundation for the resin and aggregate mixture.

-

Edging: To define the driveway and prevent the aggregates from spilling over, edging materials (such as kerbs or borders) are often installed. These elements enhance the overall appearance and functionality of the driveway.

Installation Process

The installation of a resin bound driveway involves several key steps:

-

Preparation of the Site: The first step is to prepare the site. This includes removing any existing surfacing material and ensuring the ground is level. A solid base layer is essential, so any soil or gravel should be compacted appropriately.

-

Installing the Base Layer: Once the site is prepared, a base layer of concrete or asphalt is poured and allowed to cure. This layer needs to be completely dry before proceeding to the next step.

-

Mixing the Aggregates and Resin: The aggregates are mixed with the resin in a ratio that ensures the mixture achieves the desired consistency and strength. This mixing should be done quickly to prevent the resin from curing before application.

-

Application of the Mixture: The resin and aggregate mixture is then spread evenly across the prepared base layer. This is done using trowels or squeegees to ensure a smooth finish. The surface is usually applied at a thickness of around 15-20mm.

-

Finishing Touches: After the surface is applied, it is important to allow the driveway to cure properly. This can take anywhere from a few hours to a couple of days, depending on environmental conditions.

Advantages of a Resin Bound Driveway

Resin bound driveways offer numerous advantages that make them an appealing choice for homeowners:

-

Aesthetic Appeal: One of the most significant benefits of a resin bound driveway is its aesthetic appeal. The ability to choose from a wide range of colors and aggregate sizes allows for a customized look that enhances the property’s curb appeal.

-

Durability: Resin bound driveways are highly durable and can withstand heavy traffic, making them suitable for residential driveways and commercial applications alike. The combination of resin and aggregates creates a robust surface that is less prone to cracking or fading compared to traditional materials.

-

Low Maintenance: Unlike concrete or block paving, resin bound driveways require minimal maintenance. Regular sweeping and occasional rinsing with water are typically sufficient to keep the surface clean and in good condition.

-

Permeability: A major advantage of resin bound driveways is their permeability. The surface allows water to drain through, reducing the risk of puddling and minimizing the impact on the environment. This feature also helps to prevent issues with standing water, which can lead to damage over time.

-

Quick Installation: The installation process for a resin bound driveway can be completed relatively quickly, often within a day, depending on the size of the area. This efficiency means less disruption to the homeowner’s daily routine.

Maintenance of a Resin Bound Driveway

While resin bound driveways are low maintenance, there are still some best practices to ensure longevity:

-

Regular Cleaning: Regularly sweeping the surface helps to prevent the buildup of debris, leaves, and dirt. Occasional rinsing with a hose can help keep the surface looking fresh.

-

Addressing Stains: If spills occur, it is advisable to clean them up promptly to prevent staining. Mild detergents can be used for cleaning without damaging the resin.

-

Checking for Damage: Periodically inspect the driveway for any signs of damage, such as cracks or displacements. Early detection can prevent larger issues down the line.

Considerations Before Choosing a Resin Bound Driveway

Before opting for a resin bound driveway, consider the following:

-

Local Regulations: Check local regulations regarding permeable paving and drainage to ensure compliance with any restrictions or guidelines.

-

Environmental Conditions: Consider the climate in your area. While resin bound driveways are durable, extreme temperatures may affect the curing process or longevity.

-

Professional Installation: Ensure that the installation is performed by qualified professionals to avoid issues with quality and durability. Proper installation is critical for achieving the desired results.

-

Cost Factors: While the article does not address specific costs, it is essential to consider your budget and seek quotes from reputable contractors.

Conclusion

A resin bound driveway presents a modern and aesthetically pleasing option for homeowners looking to enhance their outdoor spaces. With its combination of durability, low maintenance, and customizable appearance, it is no wonder that this surfacing solution is gaining popularity. By understanding the components, installation process, and advantages of a resin bound driveway, you can make an informed decision about whether it is the right choice for your property.